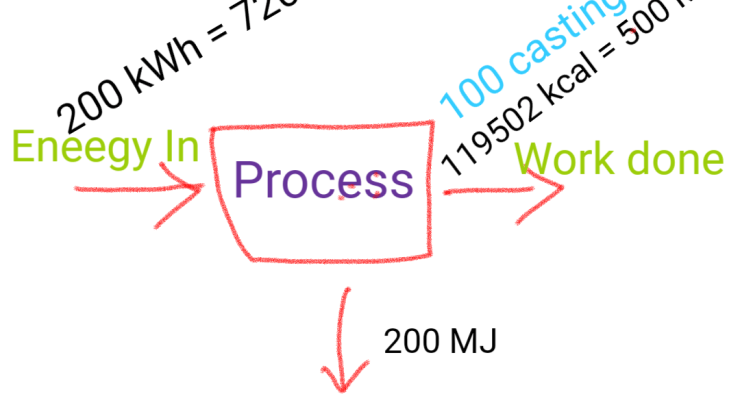

Any process takes some energy in and does some work. During this process, some energy is wasted. Now if we check the efficiency of this process, it would be – how much work is done in Joules (generally it is in kcal or number of production units – which needs to converted in some common unit) in how much energy provided to the process in Joules (generally it is in kWh in case of electrical energy)

Now, let’s take an example – In a process, say casting which involves many subprocesses like melting, pouring etc, some energy is provided in form of electrical energy to the induction furnace and pouring system. Let’s say it is 200kWh. After consuming this energy let’s say we have produced about 100 castings or production units out of that and for that it required about 119502kcal of heat energy. Let’s compute the efficiency of the process in this case.

200kWh = 200kW x 1hour = 200 kW x 3600 sec = 720,000 kW-sec = 720,000 kJ = 720 MJ

And

119502kcal = 500MJ because 1kcal = 4184J = 4.184kJ

So the efficiency should be

500 MJ out of 720MJ = 500/720 = 69.44%

This kind of information is useful to find out the amount of wastage during this process. The project must be taken to reduce this waste. The progress of the project can be identified or measured by the improvement in the efficiency of the process.

But more practical and informative way of checking the progress is to find out would be to keep an eye on how much energy required or consumed by the process for how many production units. In out case 200kWh energy is being consumed by the process to produce 100 castings or production units. So the current performance of the process is –

200 kWh / 100 production units = 2 kWh per production unit

OR

100 production units / 200 kWh = 0.5 production units per kWh

It is obvious that these parameters are easier and less costly to monitor than to measure heat energy of molten metal etc.

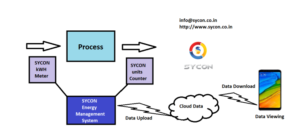

If such kind of data is easily available with the Plant Manager or Plant’s head, she can easily keep eye on the wastes in the processes. And it would be “Cherry on the top of cake” if she gets it on her laptop sitting in office or on her mobile phone while travelling across the globe. This can be done very easily using energy management systems.

So let’s wake up and get prepared for next industrial revolution Industry 4.0. And we are there with you to provide you all the vehicles to reach to Industry 4.0 standard company.

Are you ready to ride with us?