You have many machines in your industry. Most of the machines runs with the induction motor. There are three cases based on the load and moror power.

1) Rated Motor Power is matches with the load. For example – Motor is of 10HP and load fetches about 10HP.

2) Rated Motor Power is less than the load. For example – Motor is of 10HP and load fetches about 15HP.

3) Rated Motor Power is far more than the load. For example – Motor is 10HP and load fetches about 5HP.

Now we shall look each case one by one.

Case 1 – Rated Motor Power is matches with the load.

In this case, the load is fetching exact power that the motor can deliver. So this is a good case for energy saving. The Power Fcator will be near to one. The energy losses in extra current or extra mechanical wear will not be there. It is just perfect.

It is like getting the work of ox by an ox.

Case 2 – Rated Power is less than the load.

In this case load will try to fetch more power than the motor can deliver. And the motor would try to deliver this extra power by fetching more current in its windings. Now once the current in winding rises more than the current for which it is designed, it will start heating. And where there is heating loss, there is energy loss. If this heating goes on increasing, it may burn the windings and that will be a greater loss.

It is like trying to get the work of an elephant by an ox.

Case 3 – Rated Power is far more than the load.

In this case load is fetching very less power than the motor can deliver. It is a bad status for energy saving. Firstly the mechanical energy losses will be more in oversized motor than exact motor. So it will add to the energy losses. Secondly, the PF will be far less in this case which will draw more current than expected current. This will heat the cables and there will be energy losses. An oversized motor will make more winding losses. So there will be more energy losses. Third, an oversized motor will have more maintenance cost. So overall an oversized motor will fetch more energy losses which can be saved.

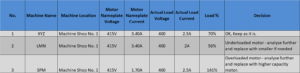

So please take a survey of all your machines in the plant. Make a report as shown in table below. This will help you to take decision. This is just a guiding line. You will have to take into consideration some other data like motor speed, the application or environmental conditions etc.

We, SYCON, can help you in this matter. For above said case 1 and case 2, where motors burn, we have a product, Intelligent motor protection relay, which saves the motor from damaging due to overloading, single phasing, jamming, locking, reverse phasing and earth faults. Click here for more information.

So let’s be proactive and save energy. And let’s save our beloved motors.

Good Luck !!