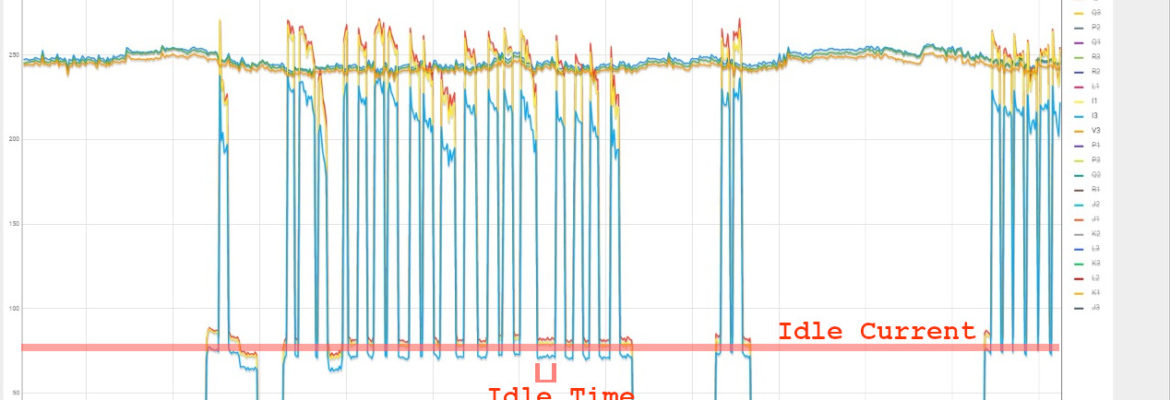

Consider any machine from your plant. Then try to figure out the actual time it is real working and the actual time it is pseudo working. By real working, we mean the task for which it is designed for.For example, in case of a milling machine, the actual cutting time is the real working time. Rest of the time is spent in activities such as fitting job on the bed, traveling of the job etc. During this time the main motor which is used for cutting purpose, keeps on running and this keeps running without any load. This running of motor without any load is called as idle running and time for which it runs in this status is called as idle time.

When we say we should check this idle running time, what does that mean? It means you must keep a watch on the idle time.When the machine is running idle –

- It is not doing any fruitful work

- It is wasting energy in overcoming the machine frictions. Energy consumed in overcoming the friction at the bearing and the friction in the machine’s other rotating parts,

So to save energy, you must strive to decrease this idle time of the machine. You may do this with following tips –

- Check if you can switch off motor when it goes in idle state and switch on it back when needed.

- If you can not do above, check if you can reduce the idle time of the machine and increase the duty cycle.

- Check if you can redesign the process and save from idle time.

We, at SYCON, have a product which will help you keep an eye on idle time and helps your to save energy. Please click here for more information. In case of any queries, please drop a message or send mail to us. We are always there to help you saving energy.

Good Luck !!